Lingmei Sports improves quality and efficiency

Release date:2024-03-29 Views:9

Since the second half of last year, affected by the market environment, badminton shuttlecock has been in short supply.

In view of the current market situation, Anhui Lingmei Sports Goods Co., Ltd. has continuously compacted production responsibility, increased production indicators, optimized production technology, and taken various measures to ensure the quality and efficiency of badminton shuttlecock.

Click the video above to watch an exclusive interview with Lingmei shuttlecock Production Line

Starting from the source, we should do a good job in the supply of feather

Feather is one of the most important raw materials for badminton shuttlecock.There is a saying in the shuttlecock factories that "those who get feathers get the market", which directly determines the quality and output of badminton shuttlecock.

The warehouse is stacked with raw feather that has just been collected, waiting to be separated."We used to wait for feather to come to the door, but now we take the initiative to go to slaughterhouses and food factories to talk about feather supply cooperation."Huang Min, production manager of Zhengda Feather Products Co., Ltd. in Wuwei County, Anhui Province (hereinafter referred to as Zhengda Company), said.

The cleaned feathers need to be dried before the following process can be carried out, and the weather is very important.More than 2000 square meters of plastic greenhouses have been set up in the open space of Zhengda Company, which is full of clean feathers.The master in charge of feather drying said: "Our drying shed has a skylight, which is ventilated in sunny days and will not get wet in rainy days, which can reduce the impact of the weather on the drying of feathers."

" From the second half of last year to now , we have added nearly 50 feather washing machines , large feather sorting machines and faetherpunching machines , replacing the original pure manual work with machines , which can not only increase the output , but also further improve the quality of feather. " Huang Min said . " In addition , we have added dozens of new employees this year , increased pre-job training ,paid attention to the old with the new , and done a good job in the talent reserve for the production of feather . "

At present, Zhengda Company has a total of more than 100 employees, with an annual output of more than 300 million pieces.

Pay close attention to production management and make every effort to ensure quality and quantity

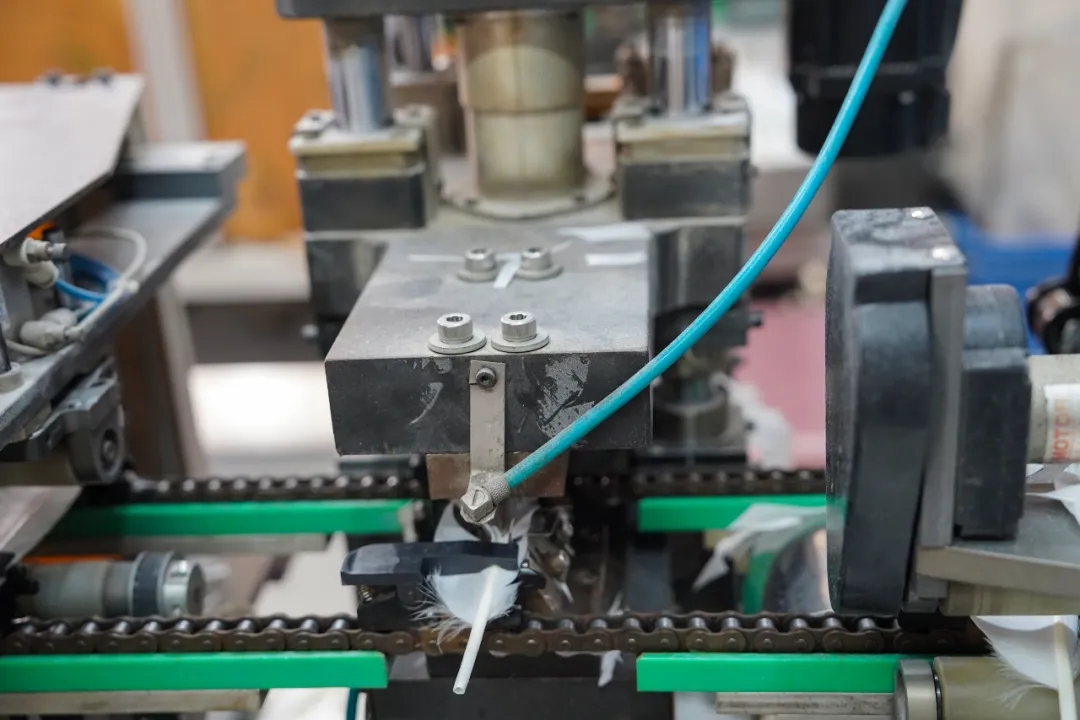

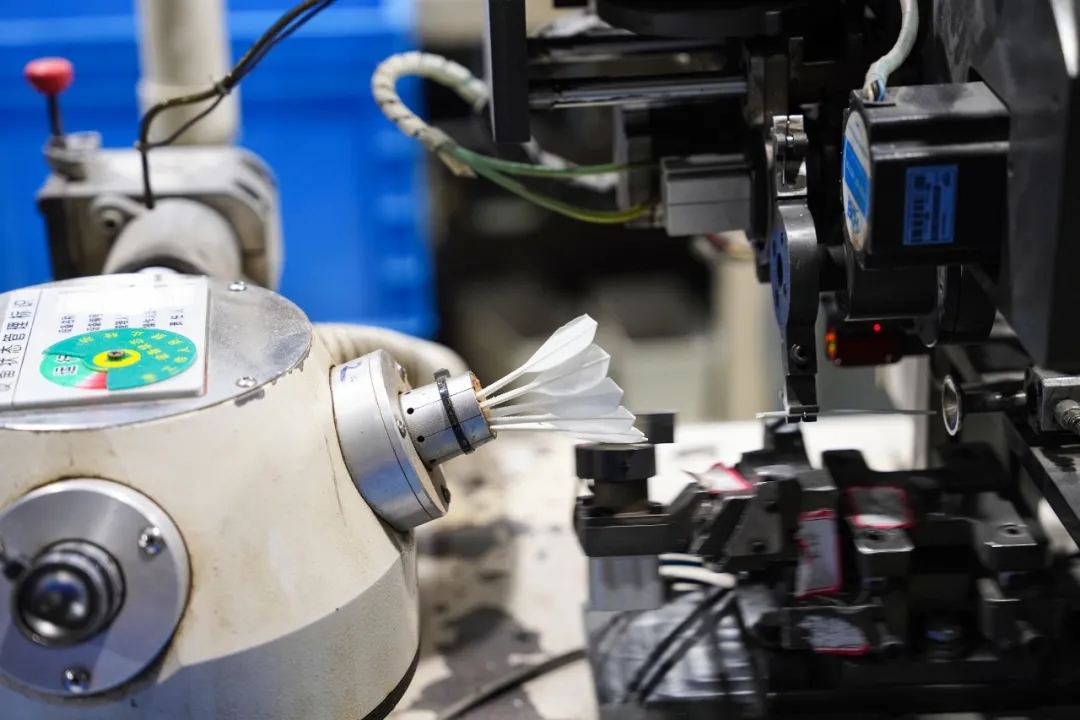

Behind a small Lingmei shuttlecock, there are dozens of processes and the efforts and sweat of hundreds of workers.In the shuttlecock production workshop of Guangming Sports Goods Co., Ltd. in Wuwei County, Anhui Province (hereinafter referred to as Guangming Company), various processes such as ball insertion, ball integration, glue injection and thread binding are being carried out in an orderly manner.

"At present, the market demand is large, we pay close attention to production management, and do our best to ensure the output and quality." Guangming Compang production manager manager Hang Renjie said.

At the weekly meeting of the Management Committee, Hang Renjie summarized the production work of last week and made arrangements for the work of this week.Hang Renjie said: "Only by constantly summing up experience, making good arrangements, defining the division of labor, and assigning responsibilities to people, can we make production more efficient."

In order to deliver the goods as soon as possible, Guangming Company has increased the production task target, implemented the delivery time rush system, and implemented two shifts for some machine-based processes without stopping work for 24 hours.,.At present, Guangming Company has more than 200 employees, responsible for all the processes of badminton production, and the annual output of shuttlecock is nearly 4 million dozen.

The output and quality are like the feather and the head of shuttlecock which are indispensable.While guaranteeing the output, Guangming Company has more strict control over the quality of badminton.

"First, clarify the quality standards, strictly control the production process, implement quality supervision, and establish a continuous improvement mechanism; second, strengthen the training of new employees, and improve the skills of production line employees; third, regularly collect customer satisfaction feedback, and implement risk management and prevention".Hang Renjie stressed.

At present, the badminton products of Anhui Lingmei Sports Goods Co., Ltd. have been distributed to 68 countries and regions such as Japan, Korea, Southeast Asia, Europe and the United States, with more than 1800 distributors worldwide.Faced with the shortage of badminton shuttlecocks in the market, Lingmei Sports is making every effort to improve quality and efficiency, ensure supply and maintain market stability.